The Battle for Chip Manufacturing: Why It Matters

The Invisible Engines Powering Our World

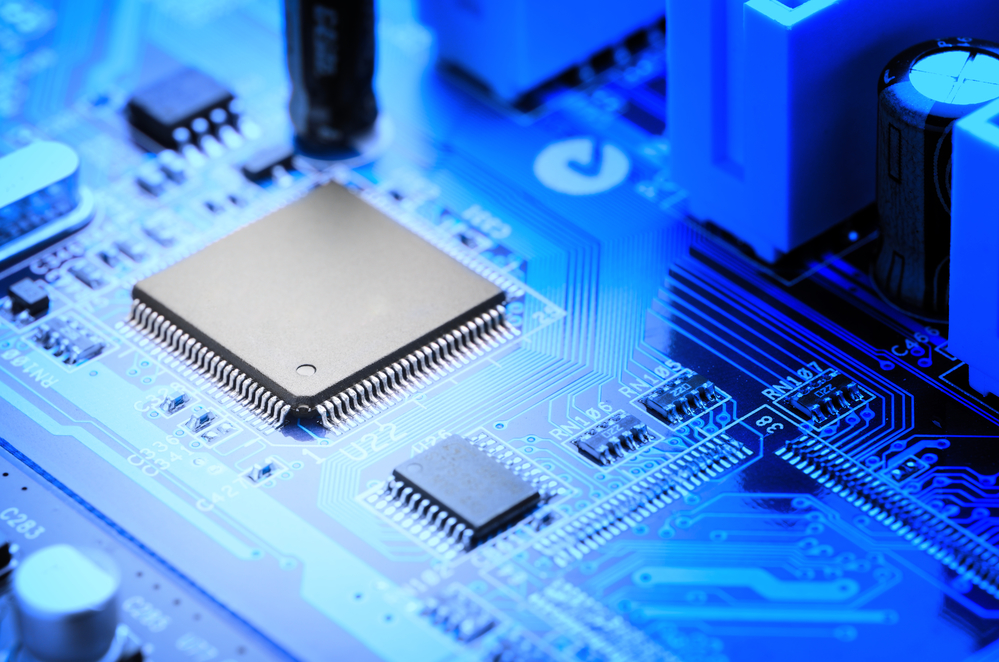

Imagine a world without chips. No buzzing smartphones in your pocket, no glowing laptops on your desk, no smart appliances to run your home, and certainly no AI to predict your next move. Hard to imagine, isn’t it? Yet, behind the screen of each device, there is a small semiconductor chip no larger than your fingernail that runs a universe of computation.

Chip manufacturing is one of those unsung heroes of modern life that few people appreciate as crucial. It is more than technology; it is an economic lifeline, a geopolitical chess piece, and a strategic necessity. Every device, every AI system, and every modern car depends on them. The race to fabricate and control these tiny silicon wonders is among the most intense battles shaping the 21st century.

Why does chip manufacturing matter so much? Why is the world watching who makes what, where, and how? Let’s dive in.

The Anatomy of a Chip: Why Manufacturing Them Isn’t a Walk in the Park

You might think, “It’s just a small piece of silicon; how hard can it be?” Well, the thing is, making a modern chip is like building a skyscraper atom by atom while blindfolded.

1. Chip Design: A Game of Precision

Every chip starts as an idea-a blueprint of circuits, logic gates, and transistors that will later power devices. Modern chips have billions of transistors, each smaller than a strand of hair. Designers use specialized software to simulate everything from power consumption to heat dissipation. One miscalculation, and the chip won’t work.

Many companies are “fabless,” designing chips but building them in factories elsewhere. The separation allows innovation without the astronomical cost of building a fab. But it also creates vulnerabilities: if the factories can’t produce the designs, innovation stalls.

2. Fabrication: Where the Magic Happens

Once the design is ready, fabrication starts. Imagine ultra-clean rooms, lasers projecting intricate circuits onto silicon wafers, and chemicals dancing across the surface with atomic precision. Each step has to be perfect because features on modern chips are measured in nanometers.

Fabs like this cost billions of dollars to build and take several years. There are only a few companies in the world that can supply the machines and know-how to make state-of-the-art chips. It’s like having a factory capable of printing currency but for the digital economy.

3. Assembly, Testing, and Packaging: The Final Hurdle

After fabrication, wafers are sliced into individual chips. Each chip undergoes rigorous testing; one defect can render it useless. Then, chips are packaged with heat management systems to make sure they survive real-world use.

Even with all precautions, this is a high-stakes, high-precision undertaking. And that’s why chip manufacturing isn’t just production: it’s an art, a science, and a gamble rolled into one.

Why Chip Manufacturing Matters: Beyond the Obvious

1. Technology and Innovation

The basic semiconductors are the engines powering every technological revolution today. Without these:

- Your phone wouldn’t run apps.

- Electric cars would not drive themselves.

- Data centers would not process the computations for AI.

Here’s the unvarnished truth: chips are not just components-they’re accelerators of innovation. Every AI model, smart home device, and connected car relies on state-of-the-art semiconductors.

2. Economic Power

Chips are at the heart of the global economy. Remember the 2020-2022 global chip shortage? Car makers like Ford and Toyota had to stop production lines. Smartphone manufacturers delayed launches. The shortage cost billions.

It speaks to a basic reality: chips are not just silicon; they are lifelines. Whoever controls production commands incredible leverage in the world of trade.

3. Geopolitical Importance

Advanced chips are strategic assets: defense systems, secure communications, and critical infrastructure run on semiconductors. Countries with fabrication can use supply chains as leverage in diplomacy, trade negotiations, or for strategic advantage.

It is no exaggeration to say chips are as critical to national security as oil once was. The race to control them is intensifying.

4. Supply Chain Fragility

The supply chain of semiconductors is global and fragile: raw materials, special equipment, and skilled labor are available only in a few regions. A disruption-a political tension, a natural disaster, or a labor strike-can send ripples all over the world.

Did you know? Some chips today rely on more than 1,000 different materials and chemicals. When one is missing, the entire production stops.

Real-World Consequences: Stories That Depict What’s at Stake

1. Automotive Industry in Crisis

New cars are a wonder of electronics; chips control everything from braking systems to infotainment. In the shortage in 2020–2022, car manufacturers had to stop production, parking their vehicles in lots while they awaited chips.

For example, Tesla redesigned some circuits to employ available chips, thus illustrating how shortages can force innovation but also disruption.

2. Consumer Electronics Delays

There were delays in launching new smartphones and laptops. Imagine waiting for the newest iPhone or gaming console, and then the factory tells you, “Sorry, no chips available this month.” It impacted millions of consumers and billions in revenue.

3. Strategic Global Investments

The recent development of governments in the U.S., Europe, China, and South Korea is to create local fabs to become less dependent on Taiwan and South Korea. These initiatives are now changing the semiconductor landscape worldwide, turning chip production into a geopolitical chessboard.

The Challenges Ahead: Why Producing Chips Isn’t Easy

- Capital Intensity: Building a fab costs billions and requires very specialized machinery. It’s not for the faint of heart. It’s something that only governments and well-funded corporations can realistically attempt.

- Raw Material Dependencies: Silicon is abundant, while ultra-pure silicon is not. Neither are specialty gases and chemical precursors. Any disruption in supply chains could lead to a shutdown of global manufacturing and send shockwaves across industries.

- Workforce Limitations: Fabs require engineers, technicians, and material scientists. Training such talent takes several years, and many regions have shortages, so human capital becomes as crucial as infrastructure.

- Environmental Concerns: Chip manufacturing consumes water and energy and produces chemical waste. Sustainability is not optional but a complete necessity for responsible scaling.

- Geopolitical Concentration: The majority of advanced fabs are located in Asia. Political tensions, trade wars, or natural disasters in this region can have an impact on the global supply chain.

Future Trends: The Road to 2030

- Expansion and Diversification: New fabs are under construction around the world. Governments and companies want to decrease dependency on just a few regions to add resilience and lower geopolitical risk.

- Technological Innovation: Future chips may implement 3D stacking, heterogeneous integration, and alternative materials that will improve performance and add a new dimension of manufacturing complexity.

- Sustainability: Sustainable scaling of production is key. Energy-efficient fabs, water recycling, and green chemical management will become the norm.

- Workforce Development: Training engineers and technicians remains a high priority. The next generation of talent will drive the innovation and operation of advanced fabs.

- Strategic Planning: Companies and governments will have to predict demand, build redundancy, and anticipate the technological needs of the future. In the end, strategic foresight will decide who controls the chips and who controls the future.

Global Implications: Why Everyone Should Care

- Governments: Chip manufacturing control ensures national security, economic stability, and technological leadership.

- Businesses: Assured semiconductor supply enables innovation, competitiveness, and profitability.

- Consumers: Chip shortages affect product availability, cost, and functionality.

- Global Supply Chains: Semiconductors are linchpins; disruptions ripple through every connected industry.

Chips, Small But Mighty. The impact of chips is monumental, even if they are tiny. Chips power innovation, shape economies, influence geopolitics, and underpin national security.

The chip manufacturing race is more than an industrial competition; it’s a defining struggle for technological and strategic supremacy. Firms and nations securing, expanding, and innovating in semiconductor production will shape the next generation of global technology.

These microchips are not only components; they form the silent engines that run the modern world. Understanding them has long since ceased to be optional; it’s become a staple.